Lifting heavy loads is challenging enough. Doing so in environments with flammable gases, combustible dusts, or vapors demands specialized equipment. An explosion-proof hoist?is an engineered lifting device designed to prevent ignition in these high-risk areas.

This guide will walk you through the critical factors for selecting the right explosion-proof hoist to ensure safety, compliance, and operational efficiency.

Key Differences Between Explosion-Proof and Other Hoists

Unlike standard hoists, an explosion-proof hoist is built with components that contain any potential sparks, arcs, or high surface temperatures within a rugged enclosure. This prevents the ignition of the surrounding hazardous atmosphere, safeguarding your personnel and facility.

Explosion-Proof vs. Standard Hoist: A Critical Comparison

Let’s have a look at what makes this explosion-proof hoist different from a standard hoist:

Feature | Explosion-Proof Hoist | Standard Electric Hoist |

Enclosure and Motor | Sealed Enclosure around brakes, motors, and electrical panels, Flameproof | Standard motor casing |

Wiring and Electrical Components | Heat-resistant, anti-spark, sealed components | General wiring and insulation |

Material | Anti-static and corrosion-resistant metals like brass wheels, copper-alloy hooks | Common industrial steel |

Compliance and Certifications | ATEX, IECEx, GB3836, etc. | Basic industrial |

Control System | Flameproof or intrinsically safe control, | Remote or regular push button |

Cost | Higher | Economical |

Maintenance Requirements | Scheduled, compliance inspections | Regular |

Performance Advantages of an Explosion-Proof Electric Hoist:

- Containment Design: Acts as a rugged shell to contain internal explosions.

- Temperature Control: Maintains surface temperature below ignition points of specific gases/dusts.

- Static Discharge Protection: Integrated grounding prevents spark risks.

Common Applications:

An explosion-proof hoist is used in environments where there is a risk of explosion during usual work activities. These industries include:

- Gas and oil refineries—?flammable vapours are always present here.

- Spray booths and paint shops—?solvent fumes make the environment highly flammable.

- Battery production lines—?such as chemical or lithium processes.

- Mining operations sites—?having coal dust or methane gas.

- Petrochemical plants—?for lifting valves, pumps, or pipes in areas where there is gas leaking.

- Chemical and fertilizer plants —with raw volatile materials.

- Feed mills and grain silos—?fine dust can easily ignite.

- Waste treatment plants—?having explosive byproducts or biogas.

If your project requires explosion-proof lifting equipment that complies with international standards (such as ATEX), you are welcome to visit WORLDHOISTS to learn about our customized explosion-proof electric hoist products, ensuring the safety and reliability of your operations.

Understanding Explosion-Proof Certifications & Ratings

Meeting specific safety standards isn’t optional for explosion-proof hoists. Companies have to meet strict safety and legal requirements. If a hoist holds a specific certification, it means it has been tested independently and approved for use in hazardous areas.

Here are common certification systems meeting the global standards:

1. ATEX (EU Standard):

This certification comes under the European Union Directive 2014/34/EU. ATEX ensures that the explosion-proof electric hoist can operate safely in potentially explosive atmospheres across the EU.

2. IECEx (International Standard):

The IECEx scheme is managed by the International Electrotechnical Commission. It follows explosion safety standards globally. It is widely recognised across Asia-Pacific, Africa, and Latin America.

3. NEC (North American Standard):

In the United States, the National Electrical Code (NEC) classifies hazardous locations into Classes (e.g., Class I, II, III) and Divisions based on the type of hazardous substance present (gas, dust, or fibre).

4. GB (Chinese National Standard):

China’s GB standard provides a detailed classification for electrical equipment used in explosive gas atmospheres. It’s used for exports and domestic compliance.

When you are comparing crane hoist manufacturers, always check that your chosen product meets one or more of these global certification standards. It’s a direct indicator of product reliability and compliance.

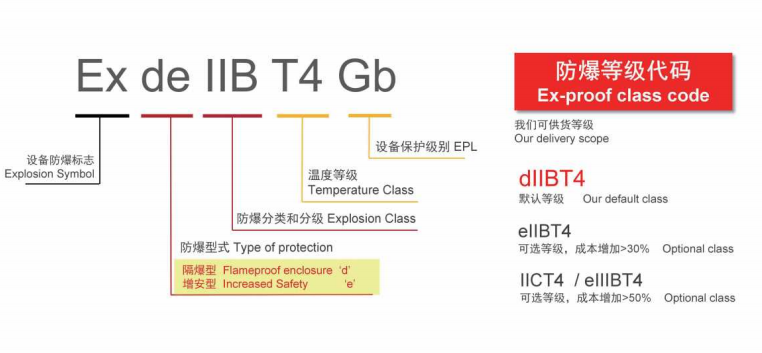

Explosion “Ex-rating”

Before you choose the explosion-proof hoist for your projects, you need to understand one term, so you make the right decision, and the term is “Ex-rating”.

This rating explains the type of protection the hoist provides and the environment in which it can operate safely.

Let’s understand it with an example:

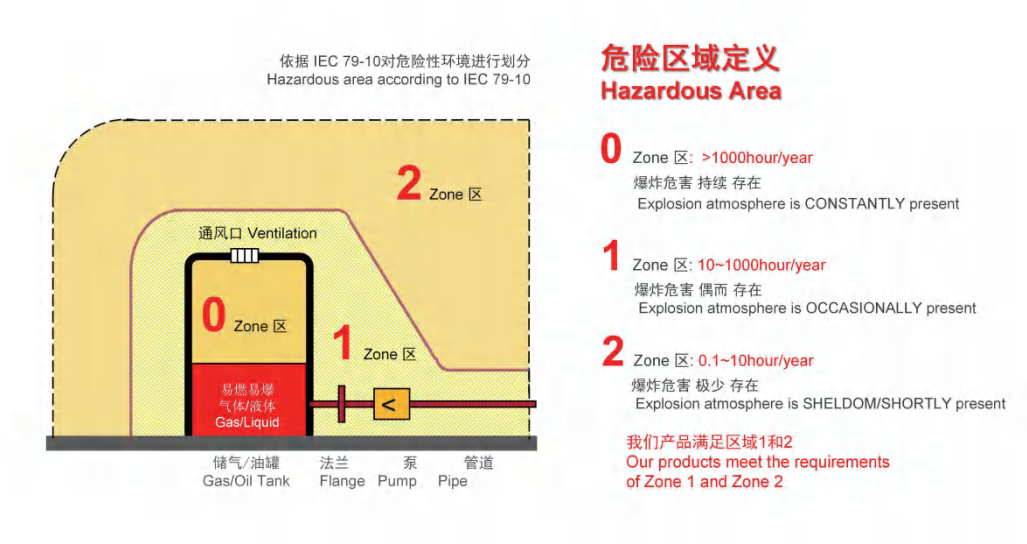

This marking helps you verify whether a specific explosion-proof hoist is suitable for your hazardous zone, whether it’s Zone 1 (high risk) or Zone 2 (moderate risk).

6 Tips for Selecting an Explosion-Proof Hoist

We need to consider a few factors very seriously before choosing an explosion-proof hoist to ensure it meets functional and safety standards.

- Verify the Hazardous Area Classification: First and foremost, identify your zone (Zone 0, 1, or 2 for gas; Zone 20, 21, or 22 for dust). Then, match the hoist’s Ex-rating accordingly.

- Check the Load Capacity and Lifting Height: Now choose a model that can handle your maximum load with some margin for safety. You can go with customizable options. Companies like WORLDHOISTS offer customizable capacities from 0.8to 80 tonnes.

- Review Certification Compliance:It’s important that you check the compliance with ATEX, IECEx, NEC, or GB standards, depending on your region.

- Consider Remote Control and Real-time Monitoring Features:Convenience and operator safety should always come first. You should choose an electric hoist with a remote control?and a real-time monitoring system. They reduce direct contact with potentially hazardous zones and help detect faults more quickly.

- Evaluate Maintenance Accessibility: Spare parts for your electric hoist should be readily available. Choose companies like WORLDHOISTS, which maintain a comprehensive parts catalogue to support your after-sales maintenance.

- Choose a Trusted Manufacturer: Always buy from established crane hoist manufacturers with proven safety records.

Maintenance and Care for Explosion-Proof Hoists

To maintain an explosion-proof hoist, the operator should receive proper guidance and training. They should understand its performance and structure. That’s why you should always read the manufacturer’s instructions for maintaining the equipment. Let’s look at essential tips for long-term reliability:

- Prevent continuous long-term use of the equipment and keep it at 80% of the rated load. It’ll prevent the hoist from overheating.

- Regularly inspect your hoist for my abnormalities.

- Operation should be stopped if the cause of the malfunction cannot be determined, and should not be resumed until the fault is rectified.

- Check the oil and brake fluid, and inspect the condition of the equipment’s seals. ?If the water, fluid, or oil is insufficient, identify the cause and rectify it.

- Use manufacturer-recommended lubricants to maintain the smooth operation of moving parts.

- Replace any damaged electric hoist parts immediately.

Get a Customized Explosion-Proof Hoist Quote Tailored to Your Facility

At WORLDHOISTS, we deliver durable, certified, and customizable explosion-proof hoists that meet international safety standards. Our explosion-proof hoists:

- High lifting precision

- ATEX-certified, compliant with EN/IEC/GB standards

- Dual flameproof and increased safety design for Zone 1/2 reliability

- Professional explosion-proof technology with multi-layer protection

- Robust performance under continuous use

- Smart real-time monitoring system (4G/Ethernet)

- Optional IIC-rated configuration available for extreme hydrogen environments

?Contact us today and get a free quote.

Frequently Asked Questions (FAQs)

Q1: Can I use a standard hoist in a hazardous area if I’m careful?

No. Standard hoists are not designed to prevent internal sparks or control surface temperatures. Using one in a hazardous area creates an unacceptable risk of explosion and violates safety regulations.

Q2: What does a typical Ex-Rating like ‘Ex d IIB T4 Gb’ mean?

It describes the hoist’s protection method (d = flameproof enclosure), the gas group it’s safe for (IIB = ethylene), its maximum surface temperature (T4 = ≤135°C), and its suitability for a specific zone (Gb = Zone 1).

Q3: How often should an explosion-proof hoist be inspected?

Follow a strict schedule: daily pre-use checks by the operator, periodic monthly inspections, and a thorough annual examination by a certified expert, as per the manufacturer’s instructions and local regulations.